Estimated Lead Times for a Laser Cutting Project in Kitchener-Waterloo

Laser cutting is a versatile manufacturing technique that works for a variety of projects, from custom signage to architectural components. When it comes to laser cutting project planning, one of the biggest aspects you’ll need to account for is lead times.

Lead times are the amount of time it takes between when the project was initiated and when it was completed. Lead times are important because it can determine whether your project is delivered in a timely manner that aligns with your project schedule.

We’ll be covering estimated laser cutting project lead times and the factors that influence turnaround times, so you can better manage expectations and avoid delays.

Average Lead Time for a Laser Cutting Project in Kitchener-Waterloo

The average lead time could be anywhere from 2-8 weeks, and potentially even longer depending on the complexity of the project. For a closer range that reflects your own project, please reach out to us for a quote. We cannot guarantee that your project will be completed within 2-8 weeks.

Average laser cutting lead times are hard to pinpoint as these projects vary widely from one to the other. More demanding projects will necessitate longer lead times than average, while smaller projects might require less time.

Outside of the production time, lead times are mostly affected by the drawing time spent on the project requirements. The drawing time accounts for technical drawing as well as the CAD file, which the laser cutting machine needs to meet exact product specifications.

What Impacts Laser Cutting Project Lead Times?

Design Complexity and Quantity of Parts

The more intricate your design, the longer it will take to program and cut. Things like fine details, tight tolerances, varying materials, and layered design will slow down the cutting speed considerably. More parts will also call for more time with material handling and post-processing, which all contribute to time spent.

Clean, well-prepared vectors and CAD files, along with automated manufacturing solutions, will significantly speed up the project time.

Machine Availability

Machine availability is a major factor in how quickly your project is completed. When multiple projects are being worked on simultaneously, machines might not immediately be available for each project. Outsourcing your manufacturing is a great way to speed up your project’s deliverables, as internal manufacturing teams typically lack the same amount of resources. However, even outsourced manufacturing projects can struggle with machine availability when juggling numerous client projects at once.

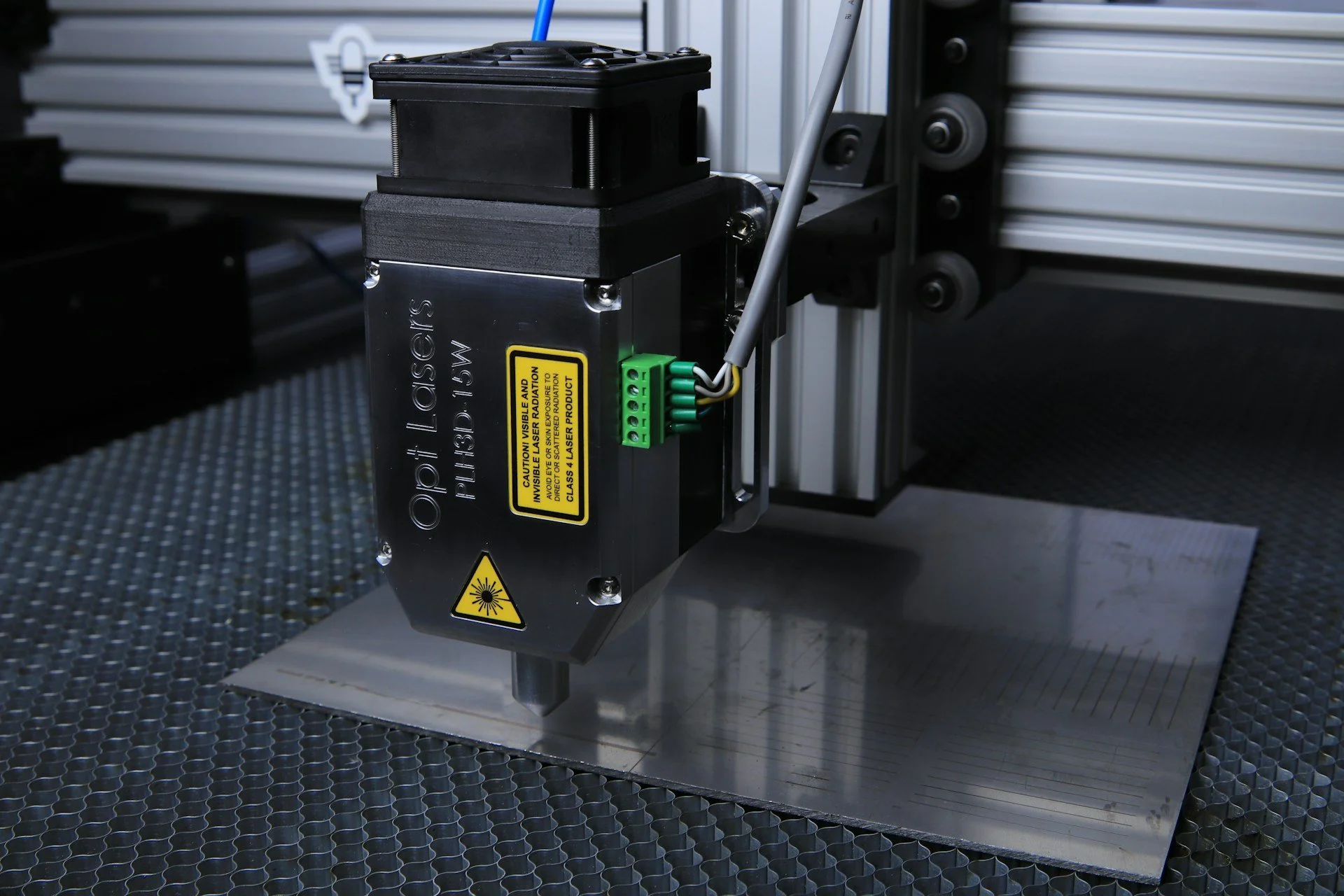

At BSG Inc., we house a wide range of industrial machines designed for high-capacity manufacturing projects. Along with our laser cutting machine, we also have a plasma cutting machine, CNC and manual milling machine, a shear, brake press, 3D printer, and much more! This allows us to meet the demands of projects requiring various manufacturing and processing techniques. If speed is a major concern for your project, we can implement different manufacturing processes to help beat machine availability.

Revisions and Design Iterations

Revisions and design iterations are essential parts of creating an effective product or component. Nevertheless, each revision and design iteration resets parts of the production process and extends the time it takes to complete the project.

Avoid losing too much time in the revision process by creating sufficient buffer time in your project schedule. Additionally, finalizing the design as much as possible before submitting will help us deliver a project that matches your specifications perfectly.

Keeping Your Laser Cutting Project on Track

To ensure your project stays on schedule, we recommend:

Communicating timeline requirements at the beginning of the project.

Asking us about options to speed up production if your deadline is tight.

Including enough buffer time in your schedule to account for revisions or unexpected delays.

Ensuring you choose materials and design specifications that are realistic if you have a short prototyping phase.

As part of our quoting process, we’ll be sure to communicate any concerns with timing and offer versatile solutions for meeting tight project deadlines.

Companies in Kitchener-Waterloo choose us because of our high capacity, tight tolerances, top quality work, comprehensive manufacturing capabilities, and convenient pickup and delivery options. If you’re looking for a manufacturing partner to help complete your project, request a quote from BSG today! We’ll show you how we can go above and beyond to meet your project timeline.