Automotive Fabrication Services

Metal Fabrication & Prototyping Services for Automotive Projects

Ball Service Group is one of Southwestern Ontario’s leading automotive fabrication partners, trusted by companies like Toyota Motor Manufacturing Canada (TMMC). From concept and design to prototyping and full-scale fabrication, our team delivers precision-built, production-ready components for automotive teams.

38+ Years of Experience in the Automotive Industry

Read About Our Experience Working with Toyota

Why Ball Service Group?

High Capacity

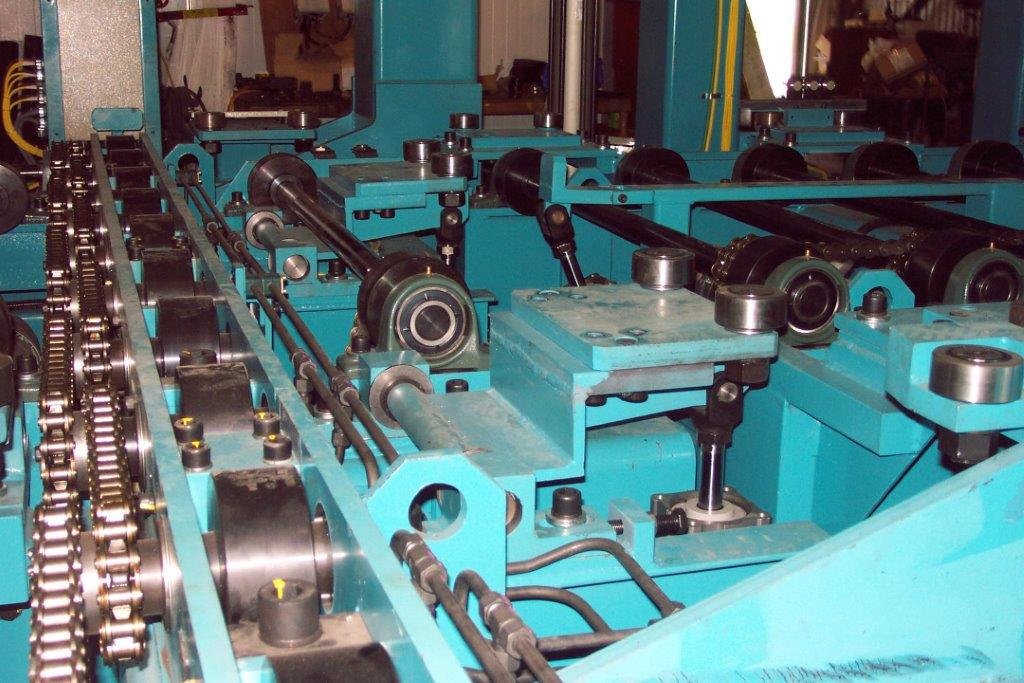

Our facility is equipped to handle projects of any scale. With our large fabrication facility, advanced machinery, and skilled technicians, we can execute large-volume automotive orders with unparalleled efficiency, precision, and quality.

High Tolerance

Our facility is equipped with multiple cutting technologies, including advanced fiber laser and plasma cutting equipment, which allow us to deliver precise, high-tolerance cuts for complex automotive projects.

Reliable, On-Time Delivery

Automotive timelines are demanding, but we deliver! Our project management, experienced fabricators, and commitment to quality ensure every part arrives on schedule. We offer delivery and pick-up options for finished components.

Kitchener Leader In Automotive Fabrication Since 1987

Our Capabilities

Powered by Industry-Leading Automation & Technology

Custom Fabrication

Shearing & Forming

Design & Prototypes

Plasma Cutting

Welding Services

Laser Cutting

Custom Fabrication for Automotive Companies

Here are some of the custom automotive components we fabricate in our facility:

Material Handling Equipment (MHE)

Robot Mounting Bases

Dollies and Racks

Brackets and Mounts

Fixtures

Stairs and Handrails

Structural Steel

Mezzanines

Prototypes

Need something fabricated that’s missing from our list?

How To Get Started

Whether you have a complete design or just an idea, follow these steps to begin your automotive fabrication project.

Step #1 - Contact us using the form below to request an estimate for your automotive fabrication project.

Step #2 - Attach your drawing or design file for review. Don’t have one yet? No worries. Our design team can help you create a detailed drawing to get started.

Step #3 - Once your order is ready, we’ll contact you to arrange a pickup or delivery time. Whichever works best for your schedule!

Step #4 - Your precision-cut automotive components will arrive ready for the next stage of your project.

Get A Free Estimate Now

Frequently Asked Questions

Can you fabricate one-off custom parts or do you only handle bulk orders?

We can fabricate one-off custom parts and bulk orders. Our team is equipped with the experience and resources to tackle projects of any size, whether it be individual component fabrication or large scale production runs.

Can you help with the design process if I only have an idea or sketch?

Yes, we can! If you have a rough sketch or just a concept, our team will work closely with you to refine the design. We'll align it with your vision as much as possible while ensuring it's structurally sound, functional, and feasible to fabricate. We can also collaborate on or take over the design process if you don’t have an initial sketch yet.

Do you offer design and prototyping services for unique automotive parts?

Yes, we can help build a prototype for unique and/or experimental automotive parts. Please let us know what you have in mind when filling out the contact form and we’ll let you know if it falls within our capabilities!

Frequently Asked Questions

-

We can fabricate one-off custom parts and bulk orders. Our team is equipped with the experience and resources to tackle projects of any size, whether it be individual component fabrication or large scale production runs.

-

Yes, we can! If you have a rough sketch or just a concept, our team will work closely with you to refine the design. We'll align it with your vision as much as possible while ensuring it's structurally sound, functional, and feasible to fabricate. We can also collaborate on or take over the design process if you don’t have an initial sketch yet.

-

Yes, we can help build a prototype for unique and/or experimental automotive parts. Please let us know what you have in mind when filling out the contact form and we’ll let you know if it falls within our capabilities!