Mining Fabrication & Machining Services

Custom Metal Fabrication for Kitchener’s Mining Sector

Built to last in high-wear mining applications.

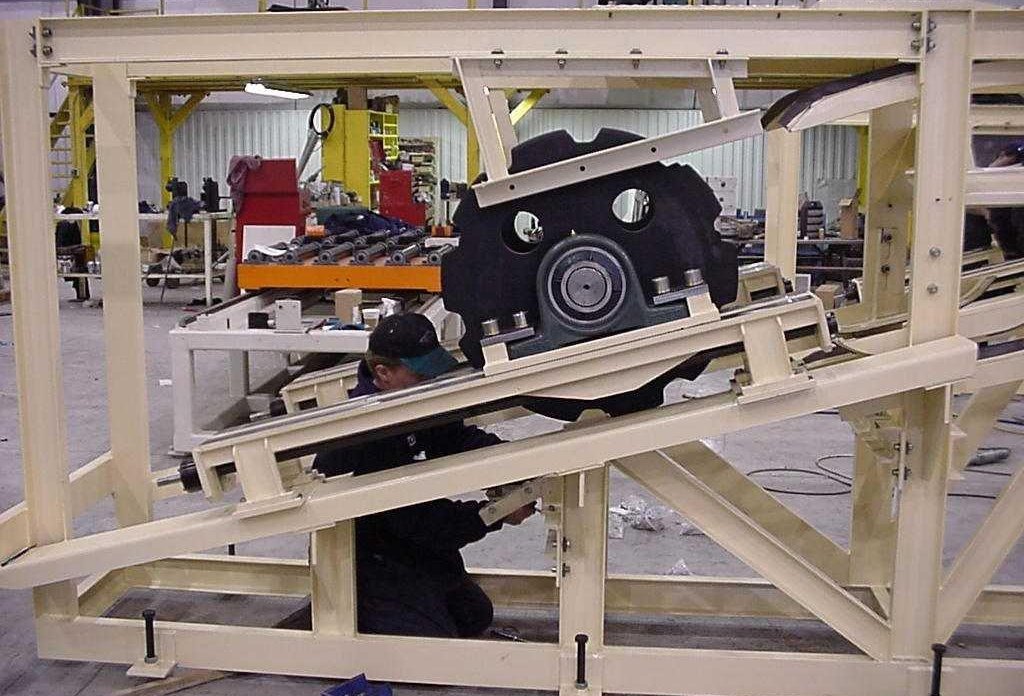

With 38 years of experience in the mining industry, we understand the need for high-quality, reliable components. Our team delivers end-to-end precision fabrication with strict tolerances, ensuring accurate fits, long service life, and reduced downtime across all mining operations.

Explore Our Durable, High-Performance Components

We machine and fabricate components built to withstand extreme wear, impact, and continuous operation. Here are some examples of what we manufacture for Ontario mining companies:

Mining Equipment Components

Shaft assemblies

Gearboxes

Tensioners

Drilling bits and rods

Wear parts for drills and boring machines

Parts and components for heavy machinery and mobile equipment

Material Handling & Processing Fabrication

Hoppers

Grizzlies

Chutes

Conveyor frames and components

Conveyor systems (guards, walkways, structural supports)

Structural & Safety Fabrication

Catwalks

Handrails

Stairs

Platforms

Access structures

Need something manufactured that’s missing from our list?

Kitchener’s Leading Mining Fabrication Specialists Since 1987

Why Ball Service Group?

Reduced Downtime

We understand how detrimental downtime is to your day-to-day operations. That’s why durability drives every material choice, weld, and fabrication we make. We are certified in industry best practices to ensure every component meets the highest standards of durability.

Custom-Engineered Solutions

Our design and prototyping team is experienced in machining and fabricating highly-customized parts for mining applications. Our tailored fabrication and machining solutions fit right into your equipment, environment, and workflow.

Fast Turnarounds

Your time matters to us, which is why we prioritize fast turnaround on every project. We are prepared to provide the timely solutions you need. With our very own delivery service, we can get critical mining components to your site without delay.

Our Process

We follow a trusted step-by-step manufacturing process to ensure your mining components meet quality and durability needs.

Free Consultation – We learn about your mining operations’ fabrication needs and challenges.

CAD Design & Engineering – We craft precise 3D designs for high-tolerance components.

Prototyping – For highly-custom designs, we build and test prototypes to ensure functionality and reliability.

In-House Fabrication – We do the cutting, forming, welding, and assembly all in one place.

QA/QC – We perform rigorous inspection and testing to guarantee durability and precision in every part.

Delivery or Pick-Up – Convenient delivery or pick-up to keep your operation on schedule.

Our Manufacturing Capabilities for Mining Operations

Backed by cutting-edge automated fabrication & machining technologies

Custom Fabrication

Shearing & Forming

Welding Services

Structural Steel

Plasma Cutting

Design & Prototypes

Fill Out This Form for a Free Estimate!

Frequently Asked Questions

-

At BSG, we offer end-to-end custom metal fabrication and machining solutions for mining operations. Our typical machining and fabrication jobs include making shaft assemblies, gearboxes, drilling bits, wear parts, conveyor systems, structural supports, and safety platforms. We are capable of cutting, forming, welding, assembling, and inspecting every component to ensure they meet strict tolerances and durability needs.

-

Yes, we frequently help mining companies create custom components from scratch, and/or replace small parts in custom heavy machinery. If you have underperforming components, we can help replace them with an improved, optimized design. Throughout our manufacturing process, we’ll work with you to design and fabricate parts tailored to your specific equipment and operational requirements.

-

Yes. We can reverse-engineer and fabricate replacement parts for legacy or obsolete machinery. Complete equipment upgrades are very costly and counter-intuitive when only some parts of the machine are have problems. Our experienced team can help with a highly-accurate, replicated replacement or improved version of malfunctioning parts.